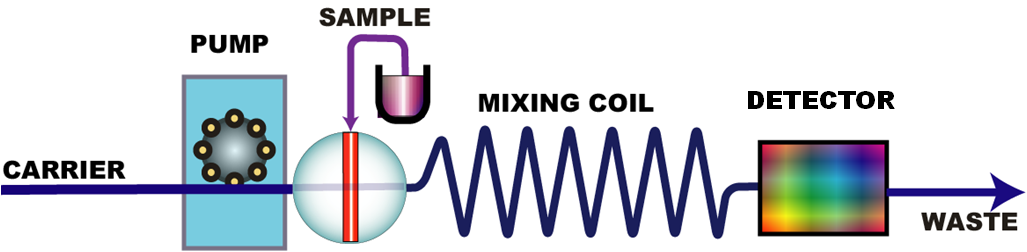

Flow Injection System

The simplest, single stream, flow injection system uses a pump that propels a carrier stream through an injection valve and into a reactor coil and through a detector. By controlling the flow rate, while processing a series of standards and samples, it is assured that the injected solutions to be analyzed are treated in exactly the same manner as they flow from injector to detector. This allows calibrations to be applied to assays of unknown samples, even if the equilibria of chemical reactions are not reached.

The flow rate is controlled by the pump which can be operated at a constant speed ( cFI) or at programmed ( pFI) speed, which generates different flow rates within an assay cycle.

A typical FI system operates at a flow rate between 1 ml/min to 2.0 mL/min, per channel. The injected sample volume is 50 to 300 microliters, channel diameter 0.8 mm, channel length up to 2 m, and operates with a sampling frequency between 1 to 2 samples/min.

1.1.4.